Introduction to the Characteristics of Precision and Efficient Welding Automation Equipment

Date:2021-10-06 Views:788

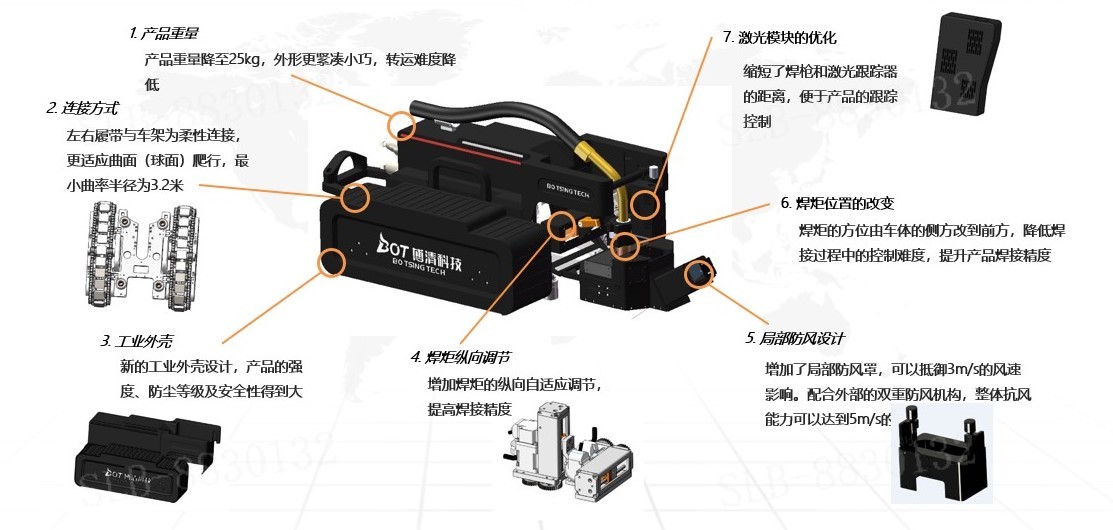

Chinese welding automation equipment manufacturing enterprises can design, manufacture, and integrate various types of specialized welding automation equipment according to different customer needs, and extensively use computer control technology. Some welding automation equipment is also equipped with a weld seam automatic tracking system and image monitoring system, ensuring the welding quality during the welding process. The technological development of China's welding automation equipment manufacturing industry shows the following trends.

Welding automation equipment is developing towards high-precision, high-quality, high-efficiency, and high reliability. It is required that all moving components and drive controls of the system have high-speed responsiveness, and electrical and mechanical devices have precise control, long-term stability, and reliability.

The integration technology of welding automation equipment includes the structural integration, functional integration, and control technology integration of hardware systems. Structural integration can be combined with module design based on different customer requirements for system functionality. And the control function module can also quickly provide different combinations of control functions. The integration of control systems can greatly reduce the amount of information and meet real-time control requirements, leveraging the corresponding judgment ability of humans in control and temporary processing.

Apply intelligent control technologies such as laser, vision, sensing, detection, image processing, and grating to welding automation equipment, enabling it to automatically adjust and optimize welding trajectory and process parameters according to the actual welding situation in various complex and changing welding conditions, achieving high-quality and efficient welding intelligent control. Intelligent welding automation equipment can not only complete the automated welding process according to instructions, but also automatically optimize the welding process and parameters based on the actual welding situation.

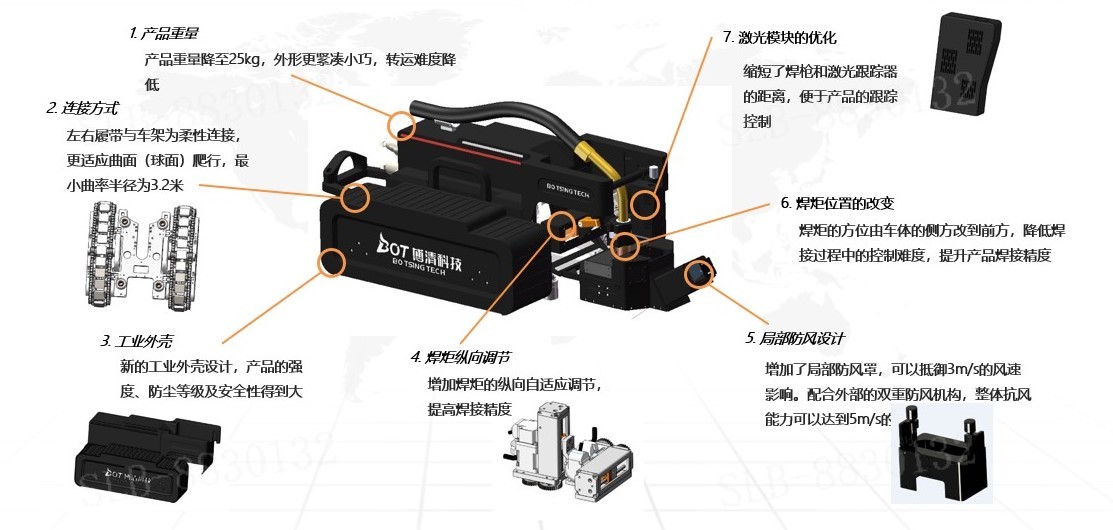

Chinese welding automation equipment manufacturing enterprises can design, manufacture, and integrate various types of specialized welding automation equipment according to different customer needs, and extensively use computer control technology. Some welding automation equipment is also equipped with a weld seam automatic tracking system and image monitoring system, ensuring the welding quality during the welding process. The technological development of China's welding automation equipment manufacturing industry shows the following trends.

Welding automation equipment is developing towards high-precision, high-quality, high-efficiency, and high reliability. It is required that all moving components and drive controls of the system have high-speed responsiveness, and electrical and mechanical devices have precise control, long-term stability, and reliability.

The integration technology of welding automation equipment includes the structural integration, functional integration, and control technology integration of hardware systems. Structural integration can be combined with module design based on different customer requirements for system functionality. And the control function module can also quickly provide different combinations of control functions. The integration of control systems can greatly reduce the amount of information and meet real-time control requirements, leveraging the corresponding judgment ability of humans in control and temporary processing.

Apply intelligent control technologies such as laser, vision, sensing, detection, image processing, and grating to welding automation equipment, enabling it to automatically adjust and optimize welding trajectory and process parameters according to the actual welding situation in various complex and changing welding conditions, achieving high-quality and efficient welding intelligent control. Intelligent welding automation equipment can not only complete the automated welding process according to instructions, but also automatically optimize the welding process and parameters based on the actual welding situation.