Process Breakthrough | New breakthrough in self-guided deep penetration welding system integration and process

Date:2023-03-29 Views:965

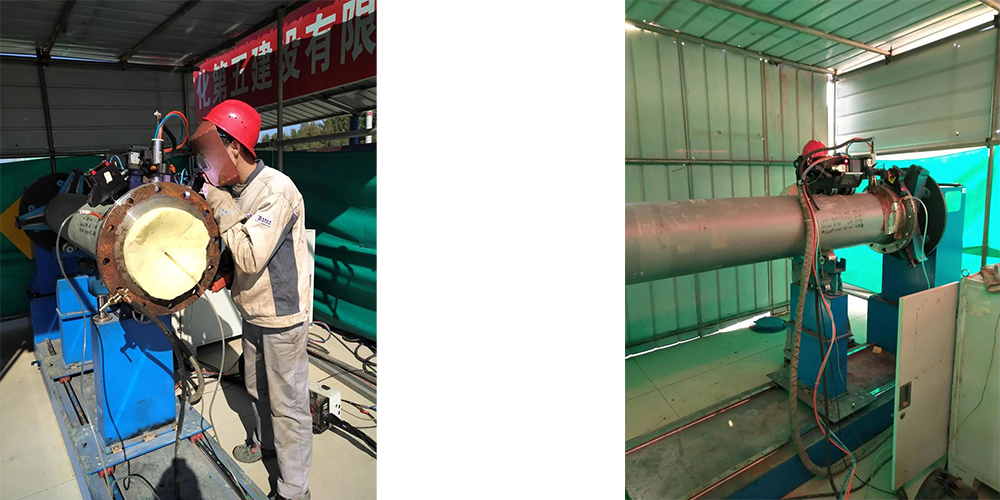

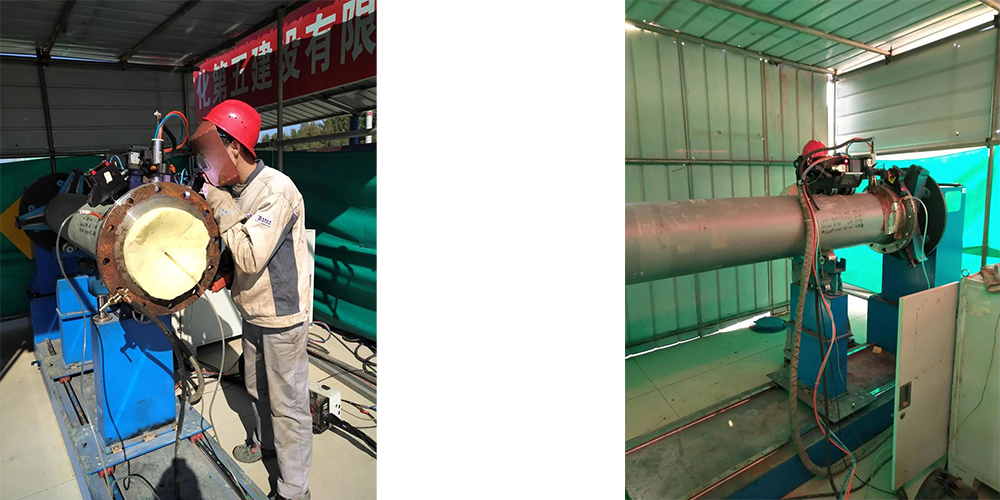

Welding is an important process manufacturing technology, which plays an important role in promoting industrial development and product progress, and is widely used in pipeline, storage tanks, ships, super high-rise buildings and other terminal scenes. In the context of promoting intelligent manufacturing, improving the level of automation, highly skilled welders limited, and continuous cost reduction and efficiency, intelligent special robots and efficient automatic welding technology have become a new development trend and urgent demand. Sinopec Fifth Construction Co., LTD. (referred to as "Sinopec Five Construction"), Guangdong Fuwei Welding Co., LTD. (referred to as "Fuwei") and Botsing Technology jointly developed the self-guided deep penetration welding system, and successfully developed the pipeline K-TIG deep penetration welding process to achieve new technological breakthroughs.

Based on the industry and market demand, the R&D team develops the deep penetration welding process, synchronously develops the deep penetration welding software communication control program and the deep penetration welding adaptive tooling, and carries out system integration. The system realizes the functions of autonomous guidance, remote monitoring, automatic welding and so on, and the operation is convenient.

Through a large number of experimental tests, the R&D team has developed a series of deep penetration welding processes such as carbon steel pipes and stainless steel pipes. In the process development stage, the 219 series carbon steel pipe and stainless steel pipe are tested, the deep penetration welding process is used as the base, and the cover is combined with gas protection welding. The steel pipe has passed the non-destructive and physical and chemical properties experimental test. Stainless steel pipe test a pass rate of up to 100%. In the process verification stage, at the project site of Maoming Port, the primary qualification rate of welding exceeded the expected target, reaching 98.15%.

K-TIG deep penetration welding is a low cost and high efficiency non-melting electrode welding method, which can be realized in practical application. There is no need to open the groove for the butt of the steel pipe below 8mm. Deep penetration welding once welding forming, the depth of penetration can reach 6-8mm, improve welding efficiency and save cost; Compared with traditional MAG welding, the welding efficiency is increased by 45%, and the labor cost is saved by more than 50%.

The pipeline K-TIG deep penetration welding system is stable, and the welding process breakthrough not only enriches the welding process parameter database of Botsing Technology, but also enriches the solution in the field of pipeline automatic welding. Brave and resolute, energetic strive to reach a new peak, Botsing technology will further consolidate the innovation ability of intelligent manufacturing technology, and continue to bring green and intelligent solutions to the oil and gas chemical industry.

Welding is an important process manufacturing technology, which plays an important role in promoting industrial development and product progress, and is widely used in pipeline, storage tanks, ships, super high-rise buildings and other terminal scenes. In the context of promoting intelligent manufacturing, improving the level of automation, highly skilled welders limited, and continuous cost reduction and efficiency, intelligent special robots and efficient automatic welding technology have become a new development trend and urgent demand. Sinopec Fifth Construction Co., LTD. (referred to as "Sinopec Five Construction"), Guangdong Fuwei Welding Co., LTD. (referred to as "Fuwei") and Botsing Technology jointly developed the self-guided deep penetration welding system, and successfully developed the pipeline K-TIG deep penetration welding process to achieve new technological breakthroughs.

Based on the industry and market demand, the R&D team develops the deep penetration welding process, synchronously develops the deep penetration welding software communication control program and the deep penetration welding adaptive tooling, and carries out system integration. The system realizes the functions of autonomous guidance, remote monitoring, automatic welding and so on, and the operation is convenient.

Through a large number of experimental tests, the R&D team has developed a series of deep penetration welding processes such as carbon steel pipes and stainless steel pipes. In the process development stage, the 219 series carbon steel pipe and stainless steel pipe are tested, the deep penetration welding process is used as the base, and the cover is combined with gas protection welding. The steel pipe has passed the non-destructive and physical and chemical properties experimental test. Stainless steel pipe test a pass rate of up to 100%. In the process verification stage, at the project site of Maoming Port, the primary qualification rate of welding exceeded the expected target, reaching 98.15%.

K-TIG deep penetration welding is a low cost and high efficiency non-melting electrode welding method, which can be realized in practical application. There is no need to open the groove for the butt of the steel pipe below 8mm. Deep penetration welding once welding forming, the depth of penetration can reach 6-8mm, improve welding efficiency and save cost; Compared with traditional MAG welding, the welding efficiency is increased by 45%, and the labor cost is saved by more than 50%.

The pipeline K-TIG deep penetration welding system is stable, and the welding process breakthrough not only enriches the welding process parameter database of Botsing Technology, but also enriches the solution in the field of pipeline automatic welding. Brave and resolute, energetic strive to reach a new peak, Botsing technology will further consolidate the innovation ability of intelligent manufacturing technology, and continue to bring green and intelligent solutions to the oil and gas chemical industry.